Barcode scanners have become easier to use than before. Gone are the days of dealing with decoder boxes and multiple cables. Simply plug the cable into your scanner and computer, and you’re up and running!

While their operation has become easier, there are now more options and kinds of scanners to choose from. Choosing the right one can be a challenge without understanding the various types and options.

The first step in finding the right scanner is to identify your specific needs:

- Where will the scanner be used? Is the environment harsh?

- How often is it used?

- Which barcode will you read?

- How do I use the scanner?

- Can you stay connected to your computer?

Understanding how to use a scanner will help you decide which scanner type to use, form factor, and other options you need. Understanding these factors will help you find the right scanner for your needs.

The type of barcode scanner

When choosing the right scanner, one of the most important issues is the type of scan engine it has. This ultimately depends on the type of barcode you’re going to read, and the aggressiveness of the units you need. There are 3 main types of scan engines:

Laser scanner

This is the most commonly used type of scanner. It uses a red semiconductor laser to read the reflectivity of the black and white space in the barcode. Laser scanners can only read standard linear (1D) barcodes, but are the most cost-effective option. Depending on the size of the barcode, a standard laser scanner can read from a few inches to a foot or two away. There are also extended-range laser scanners, such as the Zebra LS2208, which can be read from up to 35 feet away when using large reflective tags.

Linear image scanning mode

Linear imaging scanners are similar to lasers in that they also only read one-dimensional barcodes. However, instead of reading the light reflected by the laser, they took a photo of the barcode. The image is then analyzed to extract information from the code. Linear imagers, such as the AirTrack S1, have become a very good alternative to laser scanners because their read ranges and costs have become similar. Linear imagers also read poorly printed or damaged codes better than lasers. For applications that require a more aggressive scanner, a linear imager would be a great fit for the same cost.

2D area imager

Like linear imagers, full 2D imagers can capture images for analysis. But compared to linear devices, these scanners can read any type of barcode. The 2D imager supports 2D, stacked, and 2D barcodes. Another advantage of these imagers is that the orientation of the barcode is not important when reading. With lasers and linear imagers, you have to arrange the indicators horizontally on a barcode. 2D imagers can take more detailed images and are smarter, so you can read code from any direction. This will result in faster reads and less aiming. Two-dimensional imagers, such as the Runway S2, can also read barcodes on any surface, including monitors or phone screens. With their additional capabilities and very active reading capabilities, 2D imagers are becoming increasingly popular across all industries to speed up scanning applications and expand the way barcodes can be used.

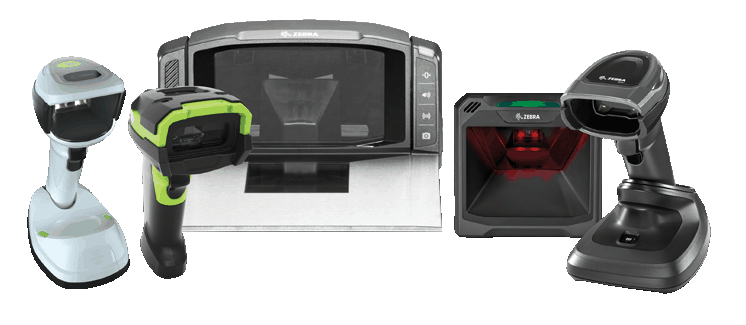

The form factor of the barcode scanner

Once you know what type of scanner you need, the next big question is the scanner’s form factor. Most of us are familiar with basic gun type and counter scanners for retail stores and grocery stores. Scanners come in 5 main form factors, each with its advantages, depending on your application and how you use the scanner.

Handheld barcode scanner

Handheld scanning is by far the most common form of scanner and is very simple to operate. Simply point the scanner at the barcode and pull the trigger. Most models, such as the Motorola LS2208, will also offer a stand for hands-free operation. Handheld scanners also increase your mobility by avoiding cable clutter in the cordless.

Handheld scanning is by far the most common form of scanner and is very simple to operate. Simply point the scanner at the barcode and pull the trigger. Most models, such as the Motorola LS2208, will also offer a stand for hands-free operation. Handheld scanners also increase your mobility by avoiding cable clutter in the cordless.

Benchtop barcode scanner

The presentation scanner, like the Zebra DS9208, is designed to sit on a countertop and does not need to be picked up or held. These scanners are designed for hands-free scanning and do not require triggering to read. Similarly, unlike handheld scanners, presentation scanners have a wider reading area to reduce the need to aim. You will find these types of scanners for retail checkout because it is easy to scan many items quickly. Just place the barcode in front of the scanner and it will read it automatically.

Mobile terminals

While they also do more than a basic scanner, mobile computers offer complete freedom because both the PC and the scanner are in one device. When other scanners need to be connected to a PC, mobile computers such as the Honeywell CT60 can move freely while storing information in internal memory or communicating over Wi-Fi and cellular (WAN) networks. Mobile computers are ideal applications that require true mobility such as inventory management and asset tracking.

Barcode scanner built into the counter

Counter scanners are similar to presentation scanners in that you simply displaya barcode in front of the reader, however, these scanners are embedded on the countertop. You’ve probably encountered this type of scanner at grocery stores and self-checkouts. Units like Magellan Data Logic 8300 are easy for any user to operate. Many models also integrate scales, fully serving POS channels.

Fixed barcode scanner

A fixed scanner is a bit more specialized than other types because it is actually to be integrated with a larger automation system. These scanners are designed to be installed in conveyor lines or kiosks without typical triggers or buttons to scan. Typically, these scanners are always turned on or triggered by an external sensor or controller. Fixed scanners have a wide range of speeds, such as the microscan MS-9, which can be adapted to any high-speed assembly line without user intervention.

Form factor by industry

| industry | Wired handhelds | Cordless handhelds | demo | Move your computer | Inside the counter | Fixed installation |

|---|---|---|---|---|---|---|

| retail | √ | √ | √ | √ | ||

| grocery | √ | √ | √ | √ | ||

| Warehousing | √ | √ | √ | √ | ||

| health care | √ | √ | √ | |||

| manufacturing | √ | √ | √ | √ | ||

| Education | √ | √ | √ | |||

| logistics | √ | √ | √ | √ | ||

| On-site service | √ | √ |

Connectivity – wired vs cordless

Each scanner must communicate with a PC in order to transmit barcode information to the software you are using. Historically, only wired scanners were connected directly to a computer via cable. These are still the most common types of scanners, usually via USB connection .serial (RS232), PS/2 file, and patented terminal connection is also available for many models. Wired scanners are easy to install and run and will be your cheapest option.

Cordless scanners are becoming more common today because their cost has become cheaper. These handheld scanners work on the same principle as wired scanners, except that the scanner communicates wirelessly with the base station. The base station is then cabled to your computer. Your computer doesn’t need any wireless support because the cradle and scanner can handle all of this. Simply plug in the stand, pair the scanner with the base, and you’re ready to scan. Replacing a wired scanner with a cordless scanner is very easy because it has no impact on your computer or software.

Most cordless scanners use Bluetooth communication, which usually gives you a range of 33 feet. There are some specialized Bluetooth and proprietary wireless devices that can transmit over 200 feet. Some models also offer additional features not available with wired scanners, such as batch memory mode and direct pairing. The Zebra CS3000, for example, can be paired directly with the device without using its stand. This makes it a perfect match for laptops, tablets, or smartphones with built-in Bluetooth. Cordless scanners offer greater mobility and no cable interference in any application.

Robustness

No matter what environment you’re using your scanner in, ruggedness always needs to be considered. Environment is an important factor, but you should also consider how to use the scanner. You may be in a standard environment, but if the scanner is abused, a more robust option will help save time and money.

Most scanners are designed for everyday use in office or retail environments. It’s okay to drop it once in a while. However, if you use a scanner in a warehouse or outdoor environment, you should consider a fairly large difference between a ruggedized and standard type like the Honeywell Granit 1911i. The sturdy unit is completely sealed and dustproof and can withstand a 6-foot concrete drop. With a rubber suitcase, they are able to deal with serious abuse. Some can even be used as hammers without any problems!

You can always tell the difference between a ruggedized scanner and a bright yellow or red housing. They may be more expensive, but the time lost when the scanner is damaged and the cost of replacing it quickly offset the initial additional cost.

Find the right scanner

All the options for barcode scanners are available these days, so it’s important to find the right device for your business needs. Determining how to use the scanner and what features are needed will make the decision-making process easier. If you still have difficulties or have other questions, please call our scanner experts. We are happy to help you.