Gs1-128 barcode production and application

The GS1 system provides accurate coding for identifying goods, services, assets and locations on a global scale. These codes can be represented by bar code symbols to facilitate electronic reading of business processes. The system overcomes the limitation that manufacturers and organizations use their own coding system or some special coding system, and improves the efficiency of trade and the ability to respond to customers.

GS1 sets standards for how business and trade items communicate with each other and is used throughout the supply chain. Creating optimized, successful barcodes is critical to the accurate flow of information.

Gs1-128 is a kind of data that can include different data in addition to the data provided by JAN code and the standard distribution code (ITF) currently available, including logistics and business transaction information.

The following data can be included in GS1-128 barcode: package number, package quantity, weight, volume and cubic volume, date of production and quality validity, lot number, address code (destination), customer current account code, customer order number.

Use E-label to label your products with compliant GS1 barcode

GS1 Application Identifier (AI)

There are about 100 application identifiers, classified as follows. Some of the data behind each application identifier is a fixed digit (standard carton ID, date, and unit of measurement). Other numbers are not fixed (lot number, serial number, package quantity, quantity, and order number).

| Classification | Content | Application identifier |

|---|---|---|

| Packaging style | ・The cardboard box code is marked on the cardboard box that packs mixed goods. ・Cardboard box codes are marked on all cardboard boxes stacked on pallets. ・Used on the ASN (Advance Shipment Notice) indicated on the SCM label. ・Sample data: (00)123456789012345675 (last digit check code) |

00 "Standard Cardboard Box ID" |

| Commodity management | ・The cardboard packaging box can meet the delivery requirements, and there is no need to mark the standard distribution symbol ITF. ・Sample data: (01)00000123000017 (last digit check code) |

01 "Delivery Container Code" |

| • Refurbishment and improvement of products ・Sample data: (20)12 |

20 | |

| • Mark the date of the product (production date, packaging date, and insurance period). ・Sample data: (11)210818 |

11~17 | |

| • Product lot number ・Sample data: (10)ABC123 |

10 | |

| • Product Serial Number | 21 | |

| Measurement instructions | • Mark the weight, cubic volume and volume on the cardboard packaging box containing the goods (food and fresh fish). | 310~369 |

| Operating | • Customer order number | 400 |

| • Commodity consignment number | 401 | |

| • Address code (company, office and specific location) | 410~421 | |

| • Internal use and any data set by the company | 90~99 |

Detailed description of GS1 application identifiers

Global Trade Item Number,GTIN

Global Trade Item Number(GTIN)Global Trade Item Number (GTIN) is the most widely used identification code in coding systems. A trade item is a product or service.

GTIN is a code called a code structure that provides unique identification for global trade projects..

GTIN has four different coding structures: GTIN-13, GTIN-14, GTIN-8 and GTIN-12.

The identification code must be used as a whole, regardless of the area of trade items applied. A complete identification code guarantees global uniqueness in the relevant application areas.

SSCC:serial shipping container code

The standard international logistics label aims to replace the confusing and repetitive labeling practices with standardized data structure, label design and label location standards. It is the best practice used to establish logistics unit labels around the world. The only requirement is that each logistics unit must have a unique serial number or "serial shipping container code" (SSCC) identification.

Serial Shipping Container Code (SSCC) is a code that provides a unique identification for logistics units (transportation and/or storage), and is globally unique. The logistics unit identification code consists of four parts: extension digits, manufacturer identification code, serial number and check code. It is an 18-digit digital code.

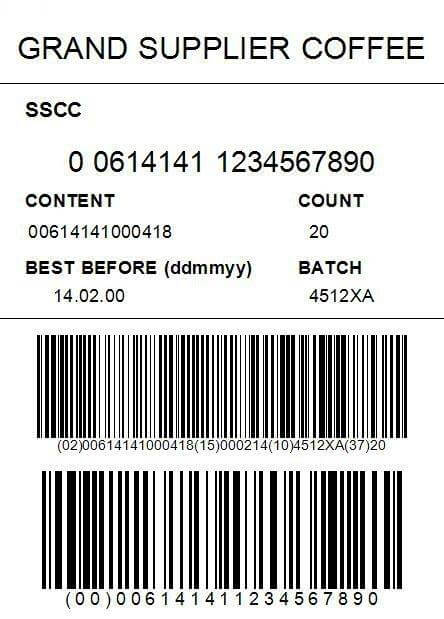

GS1 Code 128 sample data:

- (02)00614141000418(15)000214(10)4512XA(37)20

- (00)006141411234567890

A logistics unit label that contains the supplier and carrier segments

Global Location Number(GLN)

Global Location Number (GLN) is a code that uniquely identifies legal entities, functional entities, and physical entities participating in activities such as the supply chain. Participant's location code is composed of manufacturer identification code, location reference code and check code, and is represented by 13 digits.

Legal entities refer to institutions that exist legally, such as suppliers, customers, banks, carriers, etc.

A functional entity refers to a specific department within a legal entity, such as the financial department of a company.

A physical entity refers to a specific location, such as a room in a building, a warehouse or a door of a warehouse, delivery place, etc.

| Application Identifier (AI) | Type of Global Location Number (GLN) being identified |

|---|---|

| 410 | Ship to - deliver to GLN |

| 411 | Bill to - invoice to GLN |

| 412 | Purchased from GLN |

| 413 | Ship for - deliver for - forward to GLN |

| 414 | Identification of physical location |

| 415 | Invoicing party |

GLN Sample:

Global Location Number (GLN):(410)1234567890128 (The last check bit)

We are ready to help you achieve GS1 compliance label

According to the design principles of the GS1 system, the user can process the data of the GS1 system. The logic of the system ensures that the data collected from GS1 approved bar codes can generate accurate electronic information, and their processing can be fully pre-programmed.

Digital transformation of GS1 label and printing process using Easy Label. We can help you configure and deploy our barcode management system to speed up deployment and ensure that the system is implemented in accordance with best practices.