At E-Label, our business is built around barcodes. Without barcodes, the label industry would not have experienced the growth of the past 20 years. It’s easy to forget how some businesses started using barcodes and labels.

This guide is for customers who are just getting started with barcodes and need a good foundation.

Inventory management is an important management aspect for many businesses, large and small. While inventory can be tracked manually or using spreadsheets, it is more efficient to use a barcode inventory system in the long run. It’s time to take control of your inventory with a barcode inventory system that saves time, money and unnecessary work.

What is a barcode?

Simply put, a barcode is a picture with numbers or text, and the picture visually represents the data. Picture storage information and scanner, product information can be transferred to the computer immediately.

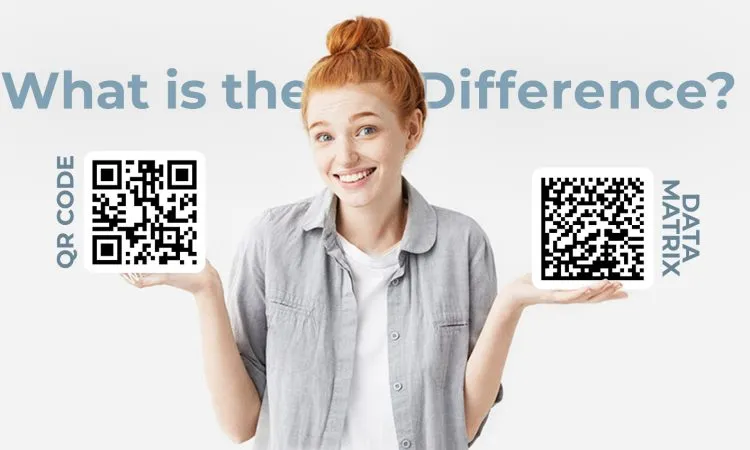

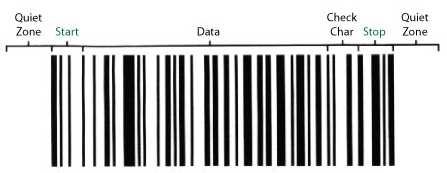

1D barcodes:

A 1D barcode consists of vertical black lines with spaces between the lines allowing the scanner to identify the product.

A 2D barcode is usually square and consists of different dots and shapes that store information. These barcodes can hold more information than 1D barcodes. 2D barcodes can also store website information, and you can scan the barcode with your phone to take you to that website.

Why use barcodes?

As businesses grow, the need for barcode inventory systems becomes more and more necessary as more inventory needs to be processed. Implementing one now will prepare you for the future while giving you some benefits!

Barcode inventory systems are far more accurate than hand-held inventory. Barcoding with humans can reduce more accurate inventory data. In fact, research shows that a person makes at least one date entry error for every 250 keys they press. The error rate of a computer is one error for every 36 trillion characters scanned.

With barcodes, you can easily find out what you have in stock and what you don’t have. When a customer buys a product, you can scan the barcode and instantly take it out of your inventory records. You’ll always have accurate and real-time inventory data, so you can make the right business decisions throughout the day.

With barcodes, all your products can be read instantly and data can be easily transferred to a computer. This will make the process for customers to checkout faster after purchasing. Instead of manually entering each product and working out the total price, the computer can do it for you.

How do I get started?

Creating a barcode inventory system is much cheaper than one might think.

First, you need to create a product code. You can have a Universal Product Code (UPC) or Stock Keeping Unit (SKU).

UPC can be found on most products and is standardized for commercial use. To receive a UPC, you can register with Global Standard 1 to obtain a unique code for your company. This code can be used to identify and track products worldwide.

UPC has many benefits. It protects your company’s brand from misappropriation, allows you to sell on online sales platforms like Alibaba, Amazon, allows customers to obtain product information online, and can be used in most inventory management systems. UPC is usually a 12-digit number for external use.

You also have the option to use custom SKU numbers for your products. SKU codes can be created manually or in inventory management software. SKUs are unique to the company and are used for internal operations such as tracking inventory, and are usually 8 digits.

From there, you need to create a barcode for each product code. You can create barcodes for free with an online barcode generator or use barcode software.

Next, you need to print your barcode. Most standard inkjet and laser printers can use label stock. However, thermal label printers are best suited for printing barcode labels. The economical cost of thermal printers is much lower than that of inkjet and laser printers. Not only that, but thermal printers are also very easy to maintain, have a longer operating life than other printers, and are fast and quiet. Thermal labels come in several different varieties.

If you are new to thermal printers, you may want to review our guide to printing barcodes and label paper options.

Select Scanner

Having a barcode is not good for your business if you don’t have a scanner to get the information from the barcode. There are a few different options when shopping for a barcode scanner.

If you’re looking for mobility and flexibility, you can get a wireless scanner. These scanners require batteries, and you’ll want to make sure you have spare batteries on hand at all times. These scanners are great for real-time inventory management, and you’re not limited by power cords. With a wireless scanner, you can save data to a memory card, put it into a computer later, connect to a computer via Bluetooth, or buy a scanner that stores the information on the device itself.

There is also an option for a wired scanner. Wireless scanners are generally less flexible than wireless scanners. The scanner needs to be plugged into an outlet and a computer where you store inventory information. Cord scanners are very easy to use and perfect for checking customers.

Small businesses will benefit the most from handheld barcode scanners, whether wired or wireless. Estimate $100 for a scanner. It may seem expensive, but the investment is worth it in the long run.

Select barcode software

There are several options for barcode software, but not every software is right for your business. Each software has different advantages and disadvantages, so it’s important to explore your options and consider your company’s needs.

We recommend Easy Label barcode software

E-label is a low-cost, simple barcode design software that is still very useful and functional. You can customize barcodes and create or connect to databases, such as reading from CSV or Excel files. Printing labels is easy, and they help ensure the final product looks the way you want it to.

E-label has a free version that meets the needs of most users.

Conclusion

As you can see, implementing a barcode inventory system is very easy and looks more complicated than it really is.

The effort to go from a manual inventory to a barcode inventory system is definitely worth it in the long run, and there are plenty of ways to get started!