POSTEK Exquisite design, easy to use and durable

As an innovative technology company and a leader in barcode/RFID printing solutions, POSTEK is committed to designing and developing products that can use technology to simplify and improve business efficiency.

Because of innovation, so not group

HEAT™ (Heating Equilibrium Adaptive Tuning) intelligent heat balance control technology is the core technology for fine control of the entire printing process.

This innovative technology completely independently developed by POSTEK, through intelligent and sophisticated algorithms, according to the printing content, real-time and meticulous adjustment of the print head heating control, greatly improving the overall performance of the Postek printer and bringing a new printing experience . Thanks to the fine control of the heating process by HEAT™ technology, the heating time during POSTEK printer work has been greatly reduced, and the comprehensive heating efficiency has been increased to more than 30%, which not only reduces energy consumption and is environmentally friendly, but also reduces the time due to high heat conditions. So that the life of the print head can be significantly improved. HEAT™ technology will be officially released on August 1, and will be applied to POSTEK’s full line of printers. At that time, the print head warranty period will also be extended.

HEAT™ technology provides solutions for clear and sharp printing

Behind the HEAT™ technology is a strong R&D team and its practice of pursuing the ultimate in quality and performance. POSTEK has a group of senior R&D personnel in the fields of material science, thin film technology, embedded microprocessor industrial control technology and mechanical structure related to thermal transfer technology. Insist on the pursuit of details and the ultimate control, based on tens of thousands of experimental tests, launched the new HEAT™ (Heating Equilibrium Adaptive Tuning) intelligent heat balance control technology, which really makes the printing effect clear and sharp.

The core of HEAT™ technology is to improve the effect of thermal/thermal transfer printing. This technology is the essence of printer products. It may seem ordinary, but its performance is extraordinary. It is with the most cutting-edge intelligent and balanced heating control technology that POSTEK can create distinctive and high-quality products for consumers.

Today we will take you to explore the HEAT™ intelligent heat balance control technology. To evaluate the performance of a printer, the most critical point is always inseparable from the clear shades of its printing effect. Next, we will first introduce several factors that affect the printing effect.

Print head

The print head is the core factor that determines the printing effect. The resolution of the print head is an important indicator of the definition. The printing effect is usually measured according to the resolution of the print head. But because thermal print head technology involves material science and thin film technology, in addition to resolution, other factors in print head design will also affect the printing effect. For example, the pursuit of abrasion resistance of the print head will cause the heat transfer efficiency to decrease due to the thickening of the wear layer, which will affect the printing effect. Therefore, heating control technology is even more important for POSTEK printers with high abrasion resistance of the print head.

Power supply management

The change of the print content is the change of the load for the power supply system; the change of the load will cause the change of the instantaneous voltage of the power supply; the change of the voltage directly affects the energy applied to the heating body of the print hair, so the power supply management also affects the printing effect Critical.

Ambient temperature around the heating body of the printed hair

For example, in the same electric kettle, the time required to boil a pot of water at a room temperature of 30°C is shorter than the time required to boil a pot of water at a room temperature of 10°C. In the same way, the temperature of the surrounding microenvironment of the heating body of the print hair will affect its heating temperature. At this time, it is necessary to collect the temperature of the microenvironment and incorporate it into the heating control system for intelligent control.

Print the heating history of the hair heater

The thermal body of the print hair that has been working all the time will have residual heat. When performing heating control, the residual heat needs to be included in the heating algorithm for calculation.

Interaction between heating elements

The heating element distributed on the print head is a micron-level precision device realized by thin film technology. Its heat capacity is very low and the thermal response speed is quite fast. Therefore, the heating conditions of adjacent heating elements will have a non-negligible mutual influence.

HEAT™ technology aims at the above factors that affect the printing effect, collects data in real time, intelligently manages data, and transmits the calculated instructions to the print head through precise and powerful data calculations, thereby achieving intelligent adjustment, balanced heating, and printing Clear and consistent in intensity.

The difficulty of HEAT™ technology lies in real-time precise control of many factors in microseconds, and it also requires extremely high software algorithms and hardware performance. It is precisely because POSTEK has always been adhering to the belief of unremitting efforts to improve product quality and precision, it has achieved the birth of this milestone technology.

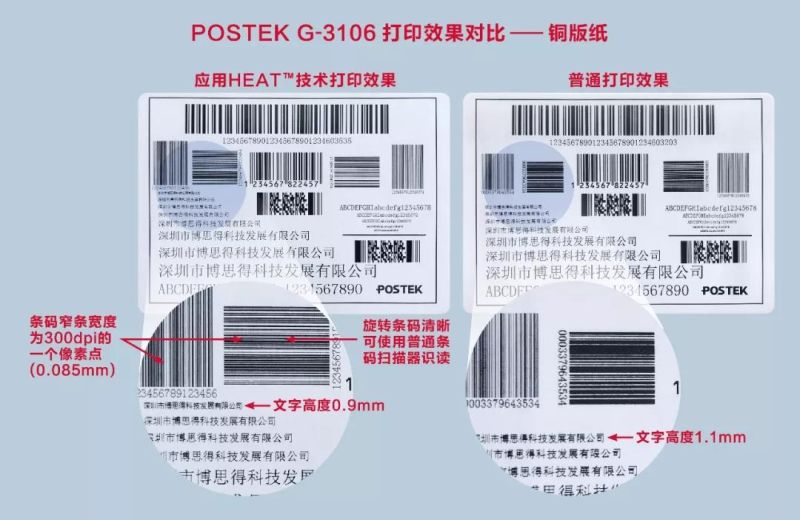

Below we use two POSTEK G-3106 printers (print head resolution 300dpi) to print the same content and test the effect.

Measurement 1: Coated paper printing

By comparing the printing effects of coated paper, we can clearly see that the barcodes and texts printed with HEAT™ technology are more precise and clear. Especially when printing rotating barcodes, the contrast is very large, and the barcodes printed without HEAT™ technology have been “pasted” together. Taking a closer look at the font comparison, the effect of using the HEAT™ technology to print a font height of 0.9mm is even finer than that of a 1.1mm font without the technology, and the density is even.

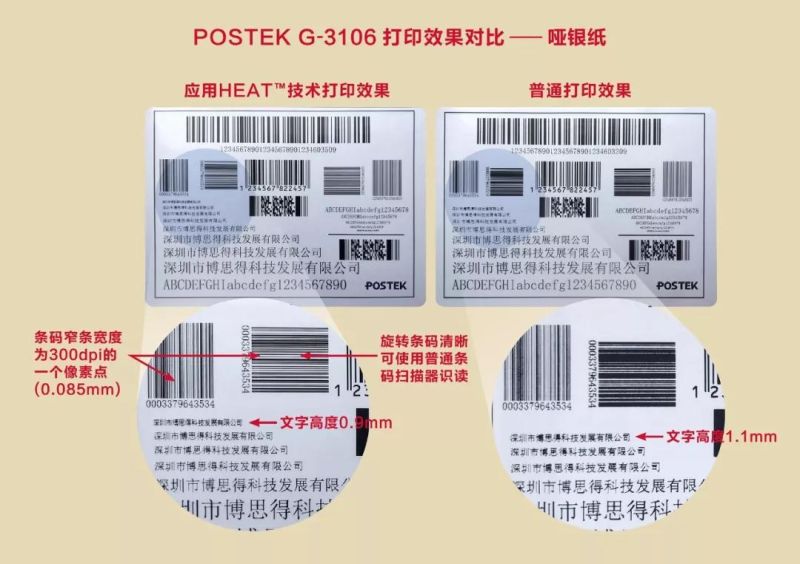

Measurement 2: Matte silver paper printing

Similar to the measured effect of coated paper, the effect of PET matt silver paper is compared. When the HEAT™ technology is used to print rotating barcodes, it can be said that the effect of not using this technology is completely better. Secondly, let’s look at the font comparison. The effect of using HEAT™ technology to print the font height of 0.9mm is compared with the 1.1mm height of printing without this technology. The density is uniform and the font is clear.

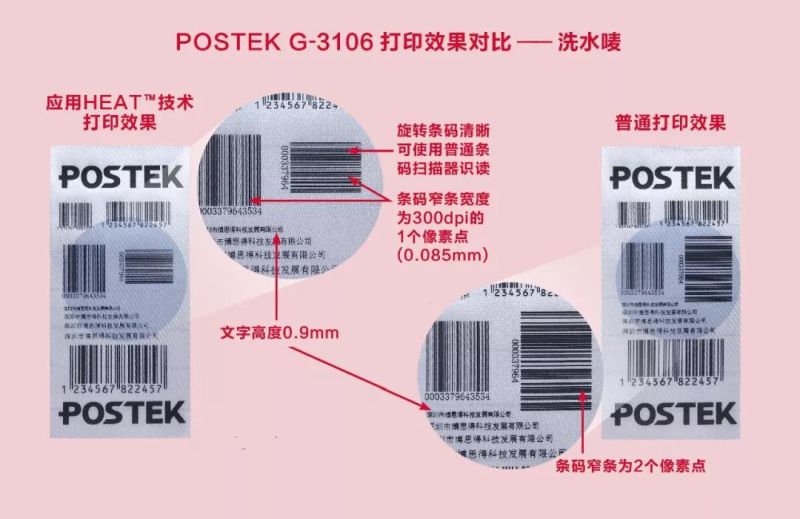

Measurement 3: Washing water mark printing

Finally, we will test the washing water mark printing. As you can see, when printing a rotating barcode without using HEAT™ technology, the same symbology and content must be magnified to 2 times to distinguish the bar and space of the barcode. The printing effect is as shown in the figure; if it is not enlarged, The printing effect is almost close to a black block. However, even if it is enlarged to 2 times, the printing effect is still not as fine and clear as the application of HEAT™ technology. Secondly, the effect of the font contrast with the same height of 0.9mm is clear at a glance.

The new “black” technology has arrived — POSTEK HEAT™ printer, intelligent temperature control, balanced heating, subverting the heating control method of traditional printers, and integrating the pursuit of the ultimate problem-solving spirit into the product, bringing an unprecedented pleasing printing experience.