Today, more and more businesses are taking their equipment management to the cloud. You can instantly get up-to-date information about your equipment checkouts by scanning QR asset tags. This eliminates the need for paperwork and spreadsheet use and simplifies the checkout process. Keep reading to learn more about how you can make equipment tracking easy.

How To Make Equipment Tracking Easy

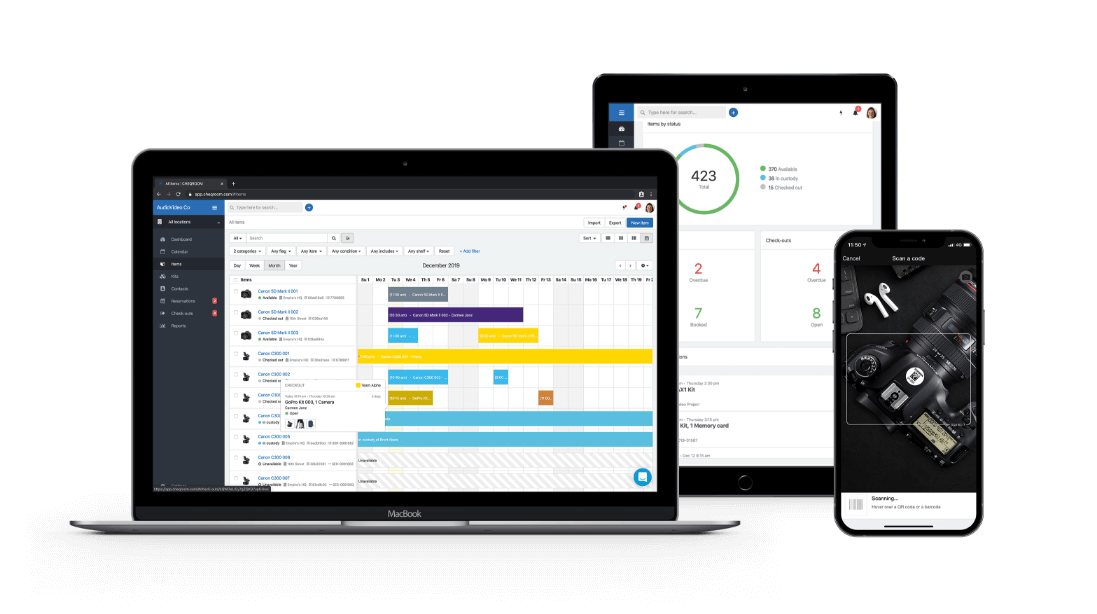

CHEQROOM is a web-based software application that helps businesses manage their equipment inventory. It allows users to keep track of what equipment they have, where it’s located, and who is responsible for it. CHEQROOM also provides detailed reports on inventory usage and trends. The software can manage any equipment, from office furniture and supplies to construction tools and machinery. It offers a variety of features that make tracking easy, including barcode scanning, GPS location tracking, and automatic updates of inventory levels.

CHEQROOM is an affordable solution that can save businesses time and money. In addition to the basic features listed above, it also offers:

- Customizable fields for each type of equipment

- User permissions so you can control who has access to which information

- Automatic alerts when items are due for maintenance or when they go out of stock

Their equipment management software supports makers on the go, from cameras and drones to IT equipment. One thing that makes their software so unique is that it’s cloud-based. This means that users can access it from any device, anywhere in the world. Whether on a laptop in your office or a smartphone on a beach, you can manage your rental equipment quickly and easily. Another advantage of CHEQROOM’s software is that it’s scalable. This means that it can be customized to meet the specific needs of your business. Whether you need to track inventory, manage reservations or generate reports.

Track equipment and assets with barcodes.

Asset tracking is the process of identifying, tracking, and managing the movement of physical assets. This can include everything from inventory and equipment to vehicles and property. Asset tracking aims to improve efficiency and reduce costs by improving the accuracy of information about assets and their whereabouts. It can also help to enhance security and compliance by providing a comprehensive audit trail.

There are a variety of different methods for asset tracking. The most common approach is to use barcodes or RFID tags to track assets. A barcode is a series of lines and numbers to identify an item. Barcodes can be scanned with a barcode scanner to provide information about the item. Cloud-based tracking uses the internet to track asset barcodes, making it easy for you to track your equipment. This approach is popular for tracking assets that are not easily tracked with other methods.

Equipment scheduling makes equipment tracking easy.

Equipment scheduling is an integral part of any manufacturing or production process. Keeping track of when each piece of equipment is scheduled to be used can help ensure that everything runs smoothly and on time. There are a few different ways to approach equipment scheduling, and the best approach will vary depending on the specific process and the equipment involved.

One popular approach is to use a master schedule that lists all the equipment and the dates and times when each piece is scheduled to be used. This can be a helpful way to get a big-picture view of the process, and it can help identify potential conflicts or bottlenecks. Another common approach is to use a line schedule that lists each step in the process and the equipment used for that step. This can help identify specific areas where equipment is overloaded or underused.

No matter which approach is used, it’s important to update the schedule to ensure that it’s accurate regularly. This can help avoid the equipment being unavailable when needed or parts being produced late because the equipment was unavailable. It can also help to reduce the risk of lost or damaged equipment and improve overall efficiency.